[ad_1]

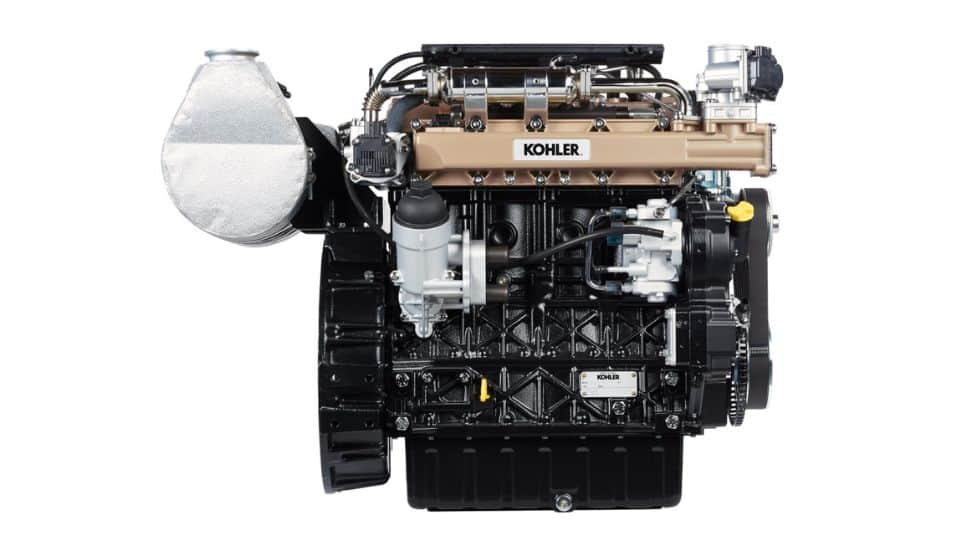

Excon 2023, presently being hosted in Bangalore is proving to be a fairly nice stage for industrial automobiles producers and gear producers. Just lately, we noticed launches from Mahindra’s industrial car and development gear manufacturing division. Kohler, a famend identify in powertrain manufacturing has additionally utilised the stage to introduce its stage V-compliant KDI engines. Because the stage V emission norms had been rolled for varied development gear automobiles, it posed a serious problem in entrance of powertrain producers.

The KDI collection of engines have been in existence for over a decade now. With the mixing of the after-treatment techniques, Kohler has managed to match the emissions with new norms with out a lot change to the prevailing {hardware} of the powerplant.

“We’re thrilled to introduce our strongest engine household, KDI, now attaining CEV Stage-V certification for Building Gear Autos together with Trem Stage-V certification for Agricultural Tractors and different Gear,” stated Vincenzo Perrone, President of Kohler Engines.

Perrone highlighted, “We’ve efficiently navigated the problem of aftertreatment system integration, providing a very built-in answer in our fashionable and superior engines. The KDI household stands as a testomony to not solely attaining compliance but additionally demonstrating resilience throughout a myriad of purposes, even underneath essentially the most demanding situations. In a market the place effectivity, reliability, and frugality are paramount, the KDI is the suitable selection for these searching for a harmonious mix of efficiency, gasoline financial system, engine longevity, and environmental duty.”

Perrone added, “This main milestone marks a big enlargement in our product choices and underscores our dedication to offering Indian clients with essentially the most superior and environmentally pleasant options obtainable.”

The Bharat Stage V improvement embodies a philosophy targeted on delivering compact engineering options, eliminating the necessity for in depth OEM equipment re-engineering. Kohler’s DPF expertise minimises downtime, positively impacting gasoline consumption and oil cleanliness, additional enhancing engine efficiency and effectivity. This engine platform is designed to supply value competitiveness and superior efficiency.